|

|

What is the cause of leakage and non-dryness in core diapers?

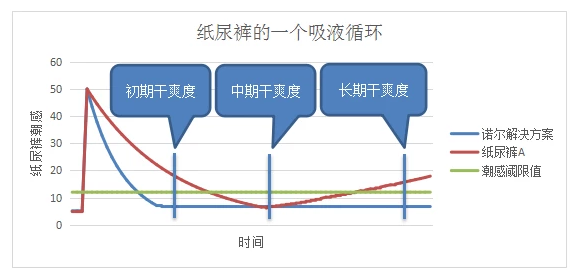

What is the structure of the core diaper, it is not necessary to elaborate, I believe that every diaper industry practitioners know that this new technology has seized the market of the fluff pulp diaper market in recent years. However, regardless of the current overwhelming advantage of core diapers in the presence of fluff pulp diapers, there has been no smear of user complaints about diapers since the core structure diapers. We will still hear complaints about core diapers such as leaking urine, such as not dry, such as red ass. Many diaper manufacturers can't completely avoid the above problems, but they know it, but they don't know why, or the problems of leaking urine and not drying out of the core diapers. Knowing its roots, the problem will be solved. To understand the problems that can occur with core diapers, it is necessary to analyze the entire process of core diapers from wearing to infants to core diapers, because different problems arise from different periods of use, and for different reasons. The use of the diaper can be based on the different periods of time after the baby is urinating, and the entire use process of the diaper can be decomposed into the initial stage of the diaper suction, the middle of the diaper suction, and the late stage of the diaper suction. Each absorbing period is not necessarily a continuous period of time, but may be discontinuous depending on the distance from the beginning of the diaper aspiration and the state occurring inside the diaper, but the internal state of the diaper has The time period of similarity. In order to facilitate the visual description of the initial, middle and late (long-term) absorption of the core diaper, a schematic diagram of an aspiration cycle of the diaper is shown in Figure 1.

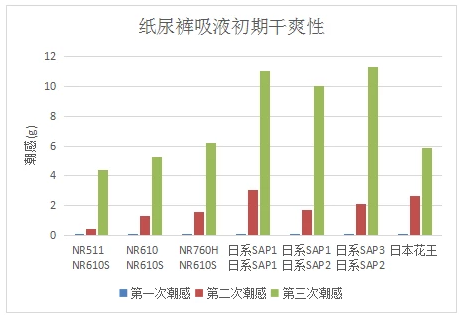

In the figure, the vertical axis represents the surface humidity of the diaper, and the horizontal axis represents the use time. When the urine is injected, the surface of the diaper has the highest tidal feeling, and then the urine is absorbed by the SAP, the tidal feeling is gradually lowered, and finally the surface tidal feeling of the diaper is stable. At a lower value, when the urine is injected again, the diaper enters the next pipetting cycle, and the tidal surface of the diaper rises again, and as the SAP gradually absorbs the urine, the surface tidal sensation of the diaper gradually decreases... The initial dryness of the diaper absorbs the liquid, which represents how fast the diaper can be from the initial sensation of the liquid absorption to the dryness, and the diaper absorbs the mid-term dryness, which represents the level of dryness of the diaper after the urine is sucked. . When the diaper does not have the next urine injection for a long time after urinating, there is a case where the diaper is re-infiltrated for a long time after urinating, or it is called diaper late or long-term dryness. Based on the entire process of diaper use, Nuoer Biotech sets the corporate standard for diaper evaluation to evaluate the entire use of diapers. We believe that only the diaper can maintain the swell threshold of the baby's discomfort during the entire use of the diaper. Below the value, the performance of the diaper can really be called excellent. Core diaper solution developed by Nuoer Bio: Upper layer NR511 lower layer NR610S; Upper layer NR610 lower layer NR610S; Upper layer NR760H lower layer NR610S; At the same time, combined with the patented flow guiding structure developed by Nuoer Bio, it can ensure the dryness of the diaper throughout the use process, as detailed below. Diapers in the initial stage of diaper absorption (Nuoer Enterprise Standard) The initial dryness of the diaper absorbs the core diaper after the liquid absorption, the surface reaches a dry state, or at least reaches the threshold of the tidal threshold that causes the baby to feel uncomfortable. Nuoer Bio has conducted a large number of experimental demonstrations and will eventually The initial dryness test of diapers was incorporated into Nuoer Bio's diaper testing company standard. The initial dryness test method is that the physiological saline is added three times, and the surface tidal feeling of the diaper is tested shortly after each addition. The initial dryness of the Nuoer biocore diaper solution is compared to the core diapers of Japanese SAP and the Japanese Kao diapers, as shown in Figure 2.

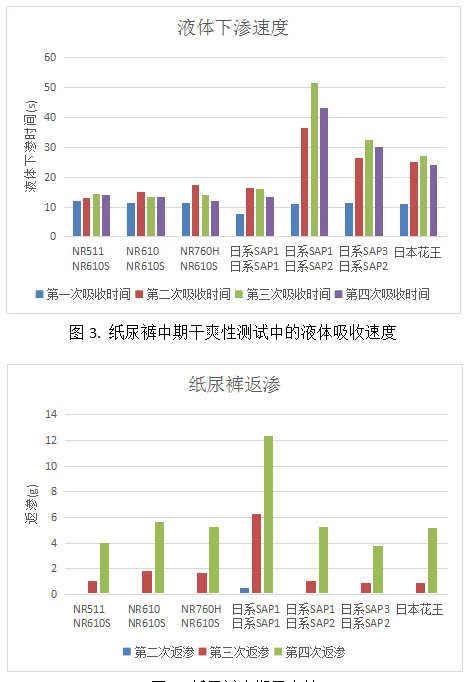

The test results show that the core diapers using the Nuoer bio-solution have better initial dryness than the Kao diapers, which is significantly better than the three full-day SAP core diapers. The significance of the initial dryness is not only the evaluation of the initial tidal sensation of the diaper, but also the possibility of leaking urine in the diaper from one side. The fluff pulp diaper species, due to the large amount of hydrophilic fibers of the fluff pulp, actually provides a space for temporary storage of liquid, which does not cause the diaper to leak urine until the SAP can not completely absorb the urine. However, because there is no fluff pulp in the core diaper (or the content of fluff pulp is very small), the space for temporarily storing urine in the diaper does not exist. Preventing leakage of urine can only be done entirely by SAP, as long as SAP is improved. Absorption speed can make ultra-thin diapers not leak urine. If SAP does not have the ability to fix urine for a short period of time, urine will flow out of the absorbent body. At this time, it is to test the three-dimensional protection of the diaper, and the three-dimensional protection of the diaper can successfully stop the liquid, and A result that is determined by a variety of factors, including the elasticity of the elastic band, the spray pattern of the rubber band, the water repellent cloth, and even the dry migration and wet migration of the surface treatment agent. In general, the urine is not completely absorbed by the absorbent body in a short period of time, and thus flows out of the absorbent body into the inside of the three-dimensional guard. At this time, the possibility of leaking urine has been greatly improved. Diaper suction mid-term dryness (Nuoer Enterprise Standard) The medium-term dryness of the diaper represents the level at which the dryness can be stabilized in the medium term after the diaper is aspirated. The medium-term dryness test method is to add liquid to the diaper for 4 times, test the liquid absorption speed, and test the diaper backflow under a heavier pressure about 10 minutes after the liquid addition. The medium-term dryness of the Nuoer bio-core diaper solution is compared with the core diapers of Japanese SAP and the Japanese Kao diapers, as shown in Figures 3 and 4.

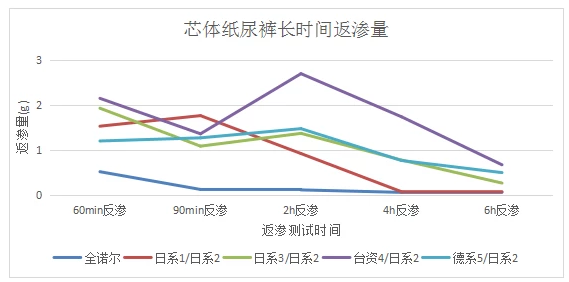

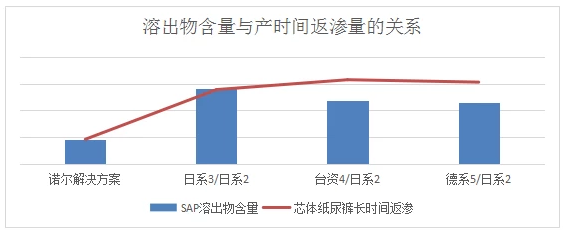

The data in Figure 5. can be summarized as: 1. The diaper of Nuoer Bio-SAP is used, and the re-infiltration is lower after adding liquid for a long time, and the amount of back oozing of the diaper becomes lower and lower with time. 2. Using the diapers of Japanese, German and Taiwanese competing SAP, the back osmosis of diapers changes with time, and within a range of 1 to 2 hours, there is a tendency for the amount of back osmosis to increase. One of the most important reasons for the high back bleed amount of diapers is that SAP absorbs water after water absorption, and the internal molecular chain of SAP breaks, which causes the water retention capacity of SAP to decrease, and the absorbed water flows out from the inside of SAP particles. The molecular chain cleavage of SAP also produces a number of low molecular weight oligomers that are soluble in water, and these low molecular weight oligomers are again dissolved. Therefore, by testing the dissolution content of SAP, the degree of degradation of SAP can be characterized. The European Nonwovens Association (EDANA) has published a standard test method for the dissolution content. According to the standard test method of EDANA dissolved matter content, Nuoer organisms tested the dissolution content of SAP produced by competing SAP and Nuoer bio-low temperature polymerization process, and the test results of the dissolution content and the long-term back-reverse amount of core diapers. Matching was found and there was a clear correlation between the two. The test results are shown in Figure 6.

The data in Figure 5. can be summarized as: 1. The diaper of Nuoer Bio-SAP is used, and the re-infiltration is lower after adding liquid for a long time, and the amount of back oozing of the diaper becomes lower and lower with time. 2. Using the diapers of Japanese, German and Taiwanese competing SAP, the back osmosis of diapers changes with time, and within a range of 1 to 2 hours, there is a tendency for the amount of back osmosis to increase. One of the most important reasons for the high back bleed amount of diapers is that SAP absorbs water after water absorption, and the internal molecular chain of SAP breaks, which causes the water retention capacity of SAP to decrease, and the absorbed water flows out from the inside of SAP particles. The molecular chain cleavage of SAP also produces a number of low molecular weight oligomers that are soluble in water, and these low molecular weight oligomers are again dissolved. Therefore, by testing the dissolution content of SAP, the degree of degradation of SAP can be characterized. The European Nonwovens Association (EDANA) has published a standard test method for the dissolution content. Nuoer Biotech tested the dissolution content of SAP produced by competing SAP and Nuoer bio-low temperature polymerization according to the standard test method of EDANA dissolved content, and the results of the dissolution content and the long-term back-reverse amount of core diapers. Matching was found and there was a clear correlation between the two. The test results are shown in Figure 6.

The data in Figure 6 can be totaled as: 1. The dissolution content of SAP has a significant correlation with the long-term re-infiltration amount of the core diaper. The lower the content of the dissolution product, the more resistant the SAP is to hydrolysis, and the lower the amount of long-term rewet of the diaper; 2. The production of SAP by Nuoer Bio-Cryogenic Polymerization Process has significantly lower dissolution content than that of Japanese competing products 3, Taiwanese competing products 4 and German competing products 5, which is the use of Nuoer SAP to obtain diapers. The main reason for the low amount of back osmosis.

Summary: After passing the test of the above diaper performance Nuoer enterprise standard, what performance should be available for the diaper can be called true dryness. The initial surface dryness of the diaper, the medium-term and long-term re-infiltration simultaneously reach a relatively good level, or below the threshold limit that will cause user complaints, "urine dampness" can truly be urinary and not wet.

|